Chemical nickel plating in the nuclear industry: atoms and utility

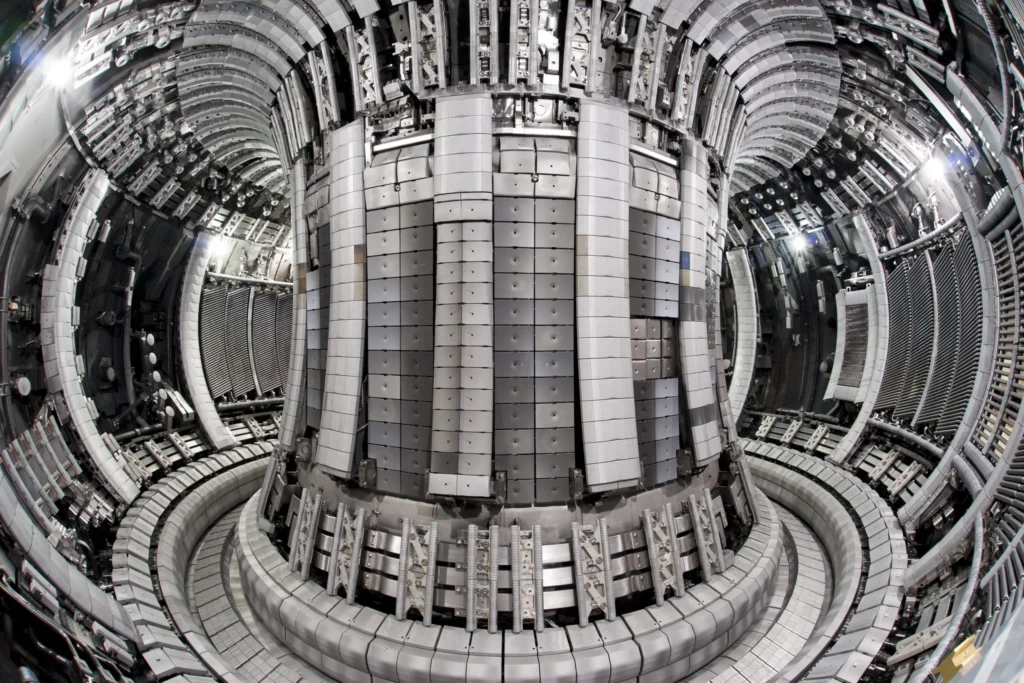

Chemical nickel plating in the nuclear industry is a crucial process involving the application of a nickel layer to components used in nuclear reactors and other nuclear infrastructure. This coating offers several advantages, including corrosion resistance, high thermal and electrical conductivity, and compatibility with high temperature and reactive environments. Nickel plating is used to protect […]

Chemical nickel plating in the carpentry industry

the application of chemical nickel plating in the carpentry industry can play several crucial roles. First, it can be used to improve the corrosion resistance of metal components, such as railings, parapets, supports, and support structures. This is especially important when such structures are exposed to weather and moisture, as is often the case in […]

Chemical nickel plating in the optical industry: let’s take a look

Nickel plating in the optics industry is a plating process in which a thin layer of nickel is deposited on optical surfaces to improve their reflective properties, strength and durability. This nickel layer can be applied to a wide range of materials, including metals, glass and plastics, providing a uniform and protective surface. Optical nickel […]

Chemical nickel plating in packaging: Structure and appearance

In the context of packaging, chemical nickel plating is a valuable technique for improving the aesthetic appearance and functionality of metal packaging. This technique is used to apply a layer of nickel to the outer surface of metal cans or boxes, giving them a shiny, corrosion-resistant finish. This not only improves the visual attractiveness of […]

Chemical Nickel Plating in the Mechanical Sector: Resistance

Chemical nickel plating in mechanical engineering is a process used to apply a protective coating of nickel to metal surfaces. This process is essential in the mechanical industry to improve the surface properties of components such as screws, bolts, machine parts and tools. Chemical nickel plating offers protection against corrosion, wear, and abrasion, extending the […]

Chemical Nickel Plating in Automotive: Innovation and Resistance

Chemical nickel plating in the automotive industry is a coating process that involves applying a layer of nickel to various components to improve their performance and durability. This technique is particularly valued for its ability to provide uniform coverage, corrosion resistance, and increased hardness of treated materials. In the automotive context, chemical nickel plating is […]

Nickel Valve Chemistry: A 5E-Based Approach

In the contemporary industrial environment, chemical valve nickel plating is a key pillar, essential for ensuring the reliability and durability of critical components in a wide range of applications. This highly specialized process involves coating valves of various sizes and types with a layer of nickel, chemically deposited to improve their surface properties. Demand: Market […]

Environmentally sustainable city in Saudi Arabia – Neom The Line – Deltar’s there

Deltar has been chosen as a supplier for chemical nickel plating of parts involved in the Neom-The Line project, the vertically developed smart city under construction in Northwest Saudi Arabia in Neom, Tabuk province, designed by eliminating roads, cars and carbon emissions. This immense project affected thousands of manufacturing entities around the world, and where […]

High quality chemical NIchelatura

Chemical nickel plating is a coating process in which a layer of nickel is deposited on a metal surface without the use of electricity. Companies that excel in high-quality chemical nickel plating are distinguished by their ability to produce uniform, high-quality coatings that improve the corrosion resistance, paint adhesion, wear resistance, and aesthetic properties of […]

Chemical and electroless nickel plating: differences and use

The nickel plating chemistry and the nickel plating electroless are two different processes of surface coating with nickel. (see in-depth Wiki and on galvanic corrosion) They differ in the process that allows the nickel layer to be deposited on the object. The common element of chemical and electrolytic nickel plating is the raw material: nickel. […]